Tip: Resin Containers

When you get your casting resin in quantity, the containers start getting pretty big and unwieldy, like the metal jugs you see to the left. Here's a trick I use to make storing resin and dispensing it a lot easier.

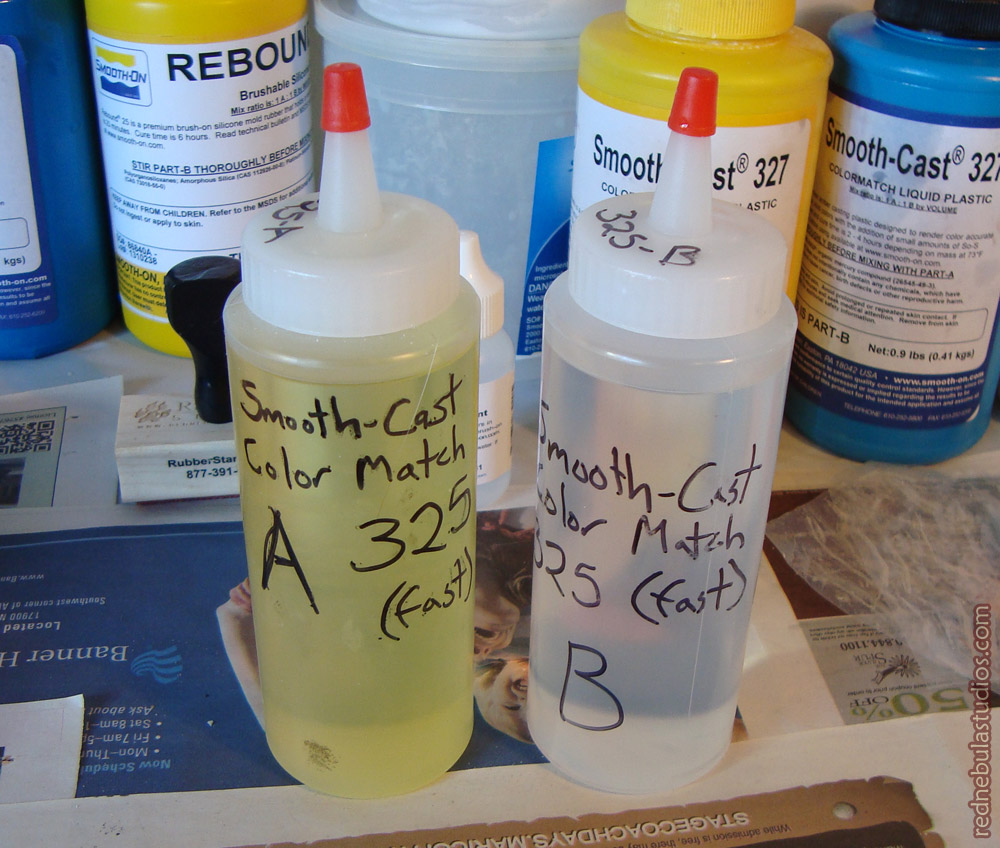

The containers shown above are 6oz. squeeze bottles made by Wilton. They or something similar are readily available from the link above or from the cake decorating section at most department or craft stores. Two important things here - make sure you get bottles labeled HDPE (more on that in a second), and make sure you are using new, clean bottles to prevent contamination that might prevent your resin from curing properly.

Make sure to shake the container of resin before pouring it into the bottle. Then, pour it into the bottle slowly and do it over a trash can in case of spills. Wear gloves and protective gear, just like you would if you were mixing or pouring resin normally. A spill is extremely messy to deal with - and yes, I know that from experience! Don't forget to clearly label each bottle. I also recommend labeling the lids; putting the wrong lid on a bottle would be a disaster!

The narrow tip makes it very easy to dispense precise amounts of resin, but removing the lid gives a nice, wide-mouthed bottle that is pretty easy to fill.

Tips:

- Since older resin can contaminate newer resin, it's a good idea to switch to a new set of squeeze bottles on a regular basis. I switch my bottles each time I go through a gallon kit of resin.

- To prevent leaks around the bottle's screw-on cap, I use a bit of plumber's tape to get a better seal.

Since I was having some issues with leaks as evidenced by the use of plumber's tape above, I've since switched to using a different type of bottle with more screw threads in the cap. The 16oz. squeeze bottles I'm using now are significantly bigger, but after using them for several months, I have not had any problems with leaks.

Plastic Types

I mentioned making sure you were using bottles labeled HDPE up there. That stands for high-density polyethylene; it's the material used for the bottles the trial-sized amounts of Smooth-On's liquid plastics come in, as you can see on the bottom of that blue bottle.

So, why is this important? I found that out when I left a bit of unmixed resin in one of my disposable mixing cups overnight. Most disposable plastic cups are made from polystyrene (labeled PS). They are fine to use temporarily while mixing your resin, but the uncured resin (Part A if you're dealing with Smooth-On products) will eventually eat through the plastic, resulting in a bunch of leaked resin on your work table and a cup that looks like this:

One final note: The information here applies to urethane resins, which are commonly used for casting opaque objects. The only epoxy resin I have at the moment came in a polypropylene container (labeled PP), so I am not sure how it reacts to HDPE or PS plastics. Your mileage may vary. :)

If you found this helpful, consider leaving us a tip or becoming a Patron! Your generosity helps our small business thrive.

Categories: Costuming, Tutorials, Materials, and Tools, Tutorials, Tips, and Tricks

Tags: container, dispensing, HDPE, high density polyethylene, liquid plastic, mixing cups, plastic, polystyrene, PS, resin, squeeze bottle, store, storing, uncured, urethane

Live Date: 12/31/2013 |

Last Modified: 9/29/2022