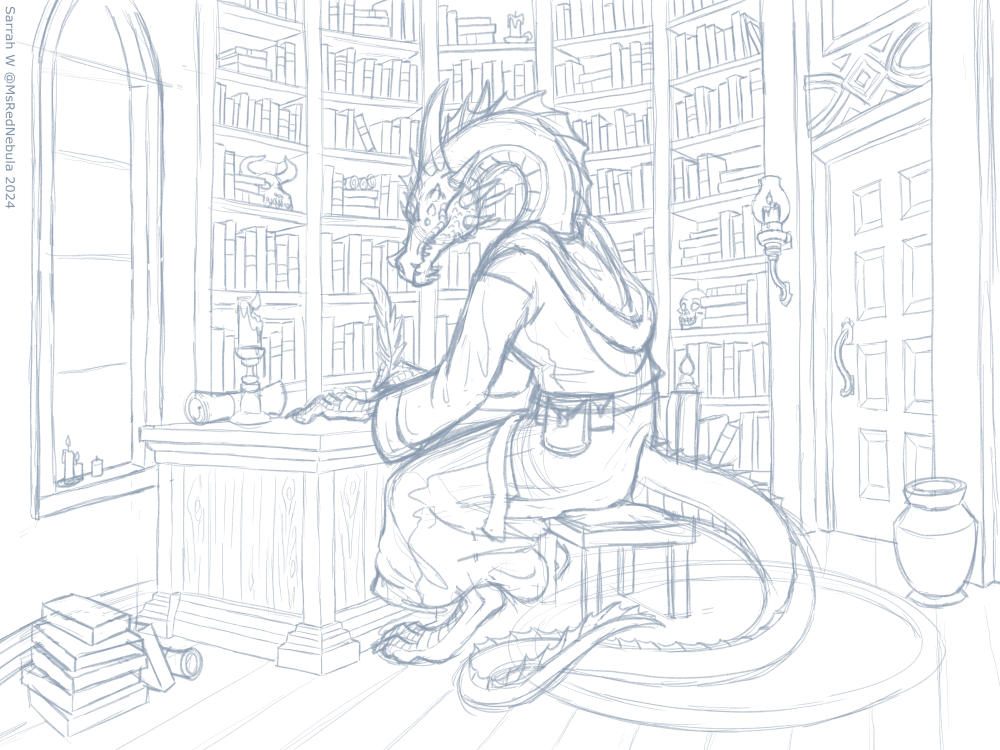

Wizard's Study - WIP Sketch

Sarrah Wilkinson - 12/7/2024

Here's a sketch for a piece I've been working on for a while.

If you're interested, the full color version is up on my Patreon now, with the timelapse coming within a few days.

Categories: Artwork

Tags: anthropomorphic, books, bookshelves, chair, desk, dragon, fantasy, library, sketch, study, wip, work in progress

Live Date: 12/7/2024 |

Last Modified: 12/7/2024

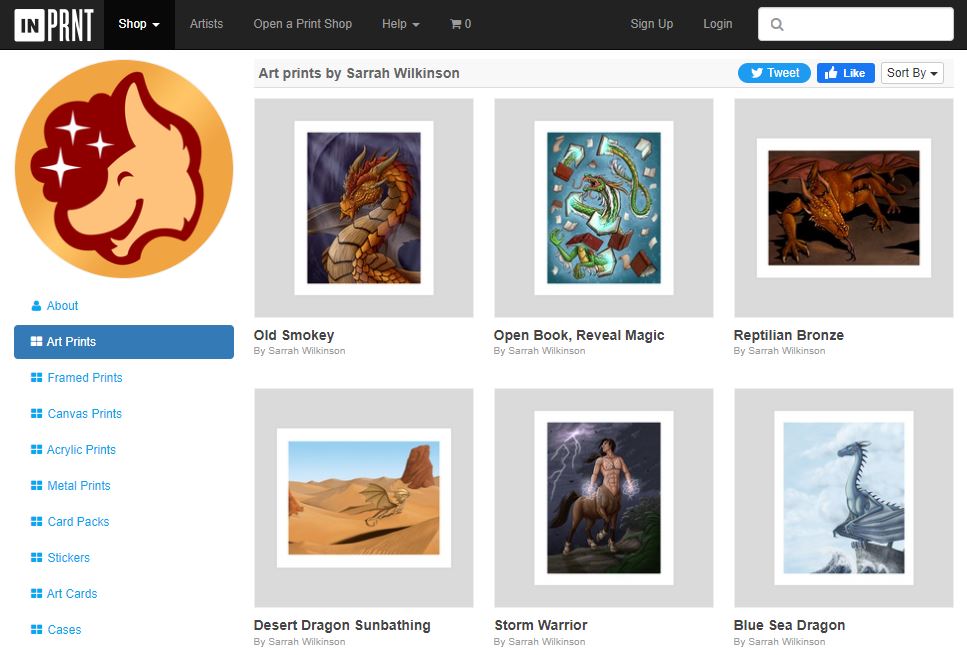

New INPRNT Shop Now Open!

Sarrah Wilkinson - 6/7/2023

I'm happy to announce my new INPRNT shop! I set up a shop there because I'm very impressed with their dedication to offering high-quality prints, made in the U.S.A., and with a very fair percentage of each sale going to the artist. Not all of my work is up yet, but if there's a particular piece you want to see, please let me know.

They offer full archival quality giclée prints, wrapped canvas, frames, acrylic and metal prints, as well as cards, stickers, and even phone cases. Since everything is printed when it's ordered, they can also offer a greater variety of sizes than I'm able to do through our own Etsy shop.

Categories: Artwork

Tags: art, art shop, INPRNT, pod, print on demand, shop

Live Date: 6/7/2023 |

Last Modified: 6/7/2023

New Tutorial: Custom Brush Tips

Sarrah Wilkinson - 4/4/2023

I just added a new tutorial: Tutorial: Custom Brush Tips in Clip Studio Paint (Video)

Categories: Artwork

Tags: brush, brush tip, Clip Studio Paint, CSP, custom, how to, tutorial

Live Date: 4/4/2023 |

Last Modified: 4/4/2023